Digital Restoration: The Normandy Liberty Bell

The famous bell tolled throughout the history of colonial Pennsylvania and the early United States, marking historical moments such as the Boston Tea Party, the signing of the Declaration of Independence and the ratification of the Constitution.

Nearly 100 years after the bell was cast, the bell had begun to crack. In February of 1846, while being rung in commemoration of Washington’s Birthday, the bell retained the crack that we are all familiar with today. The infamous cracked bell traveled the country visiting expositions, celebrations and the Chicago World’s fair. The bell was continually “tapped” to symbolize liberty and independence on monumental occasions such as the 150th Anniversary of American’s independence and on the WWII D-day invasion of Normandy. return to full slide show The Challenge:

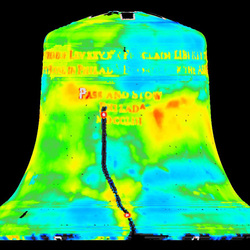

Direct Dimensions was given the task of creating an exact digital replica of the Liberty Bell that would be cast to look and sound before it cracked in 1846. return to full slide show The Solution:

|

ApplicationsDigital Molds

3D Archiving Digital Sculpting Restoration Replicas and Editions Enlargements and Reductions Crating and Exhibits Research and Analysis Fundraising Services |

[email protected] copyright 1995-2013 Direct Dimensions, Inc 410-998-0880